With over 25+ installations all over India, Atom series’s successful ranges can perform all micro grinding process on flat surface, profile, rod, machine tool, die mould, mechanical precision components.

We have Basic, Prime, Diemould, Premium series which contains grinding basic manual model, NC model, CNC model and Die Mould dedicated model.

Advantages

- Good casting and rigid body

- Good cost-performance ratio

- Long-term precision

- Comfortable controls

- Easy to operate

- Proven components

- The Optimal 90° benefit

- Training and support

| Machine Type |

Unit |

ATOM 63 (Manual/NC/CNC) |

ATOM 84 (Manual /NC/CNC) |

ATOM 115 (NC/CNC) |

ATOM 136

(NC/CNC) |

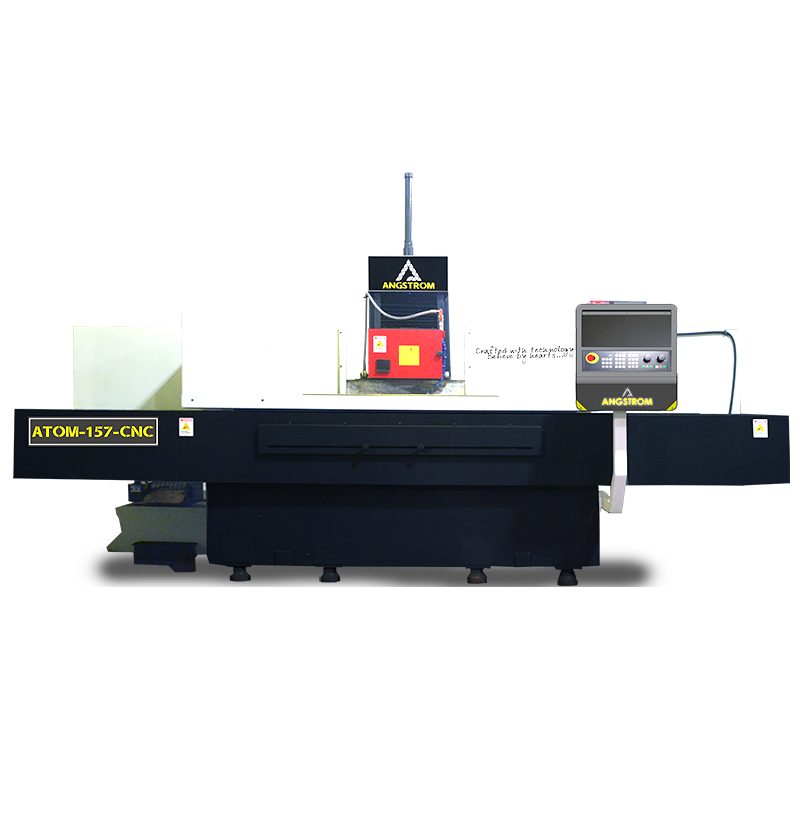

ATOM 157

(NC/CNC) |

| Grinding Area ( L x W ) |

mm |

600x300 |

800x400 |

1100x500 |

1300 X 600 |

1500 X 700 |

| Longitudal Travel |

|

|

|

|

|

| ( X Axis) |

mm |

650 |

850 |

1150 |

1350 |

1550 |

| Cross Travel ( Z Axis) |

mm |

305 |

400 |

510 |

630 |

730 |

| Distance table Surface to spindle center |

mm |

400 |

530 |

530 |

650 (Opt-800) |

650 (Opt-800) |

| Grinding Spindle drive |

kW |

2.2 |

4 |

5.5 (Opt-7.5) |

7.5 (Opt-60) |

11 |

| Grinding Wheel Dimensions |

mm |

200 x 20 x 50.8 |

300 x 50 x 50.8 |

350 x 65 x 127 |

350 x 65 x 127 |

400 x 100 x 127 |

| Machine Dimension |

|

|

|

|

|

| [L x W x H(max)] |

mm |

2600 x 2000 x 2300 |

3400 x 2300 x 2400 |

4300 x 2600 x 2500 |

4700 x 2600 x 2500 |

5500 x 3000 x 2800 |

| Machine Weight (approx) |

kg |

2100 |

3500 |

5000 |

6500 |

7500 |

Advantages at a Glance